Case Schelde Exotech

Unique NDT methods on riser forgings

Read more

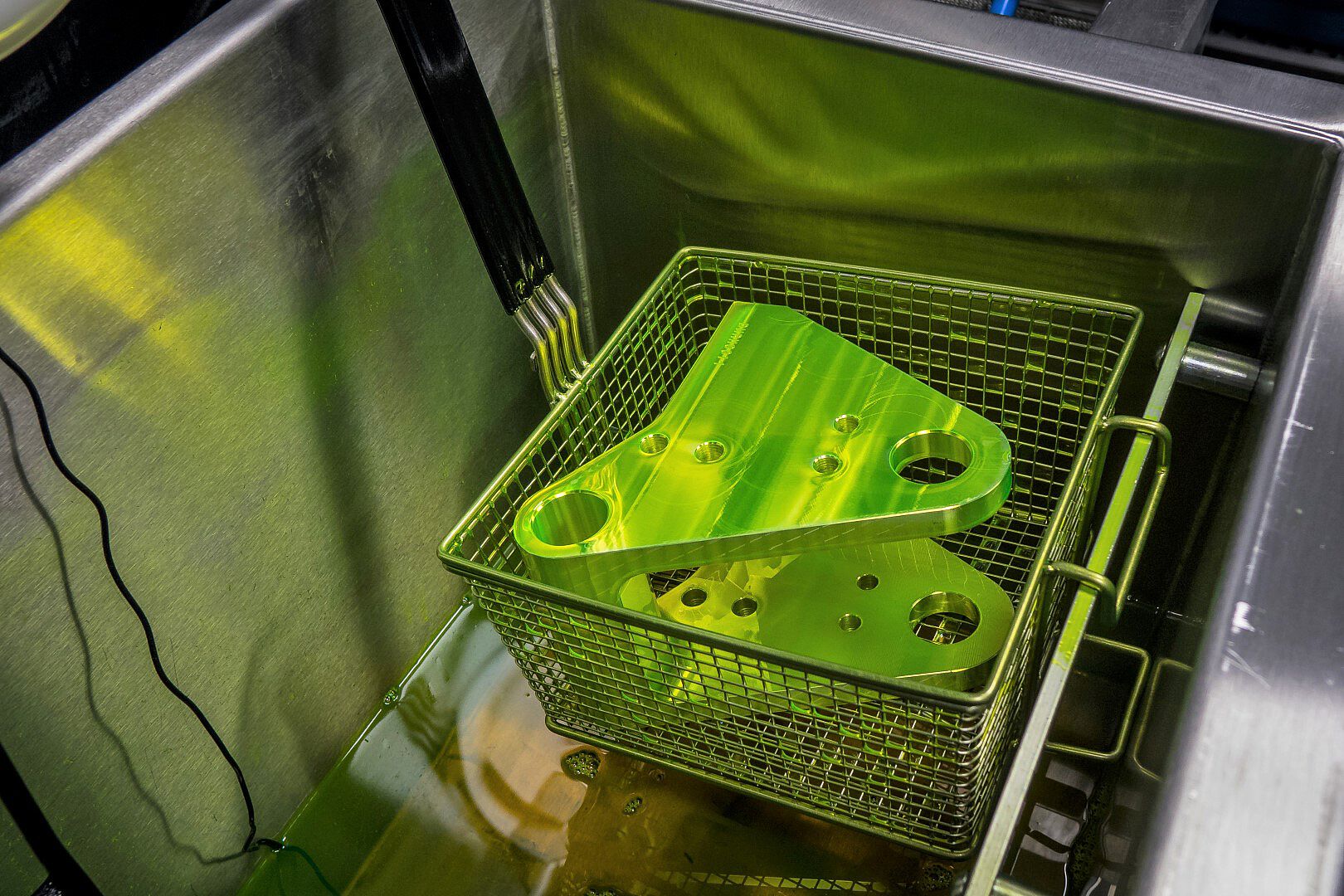

Dye Penetrant Testing (PT) is used to find surface breaking defects. PT inspection is suitable for a wide variety of materials, but it is mainly used on non-ferrous metals. This method makes use of the capillary action principle. A liquid dye with low viscosity is applied to the test piece. Due to its low viscosity, it gets sucked into surface-breaking discontinuities. After allowing adequate penetration time, the excess penetrant liquid is rinsed off. After drying, a chalk-like developer is applied. The developer draws the penetrant dye from defects making a visible indication that can be interpreted by the inspector.

Contact us if you have a question or want to receive a quotation!

No. Non-relevant indications can appear because of inherent surface roughness or seams. Fingerprints or fibers can also produce non-relevant indications.

PT testing is useful immediately after any manufacturing process which is known to cause discontinuities. Therefore, it may sometimes be performed more than once during the manufacture of a part. It is important to carry out penetrant inspection before machining operations such as shot blasting, peening or grinding which can prevent penetrant inspections from finding these discontinuities.

Time

MT: fast inspection technique

PT: relatively slow process

Materials

MT: can only be applied in examination of ferromagnetic materials

PT: provides optimal results in all metals and alloys

Discontinuities

MT: detects not only surface cracks but also imperfections that are very near to the surface

PT: only detects discontinuities which are on surface and open for the dye to penetrate

Surface conditions

MT: no pre-cleaning and post-cleaning processes are necessary because surface pollutants don’t have adverse effect on inspection results

PT: Strict pre-cleaning is required

Temperature

MT: is applicable up to extreme temperatures (normally below Curie temperature)

PT: limited temperature conditions (5-60 degree Celsius)

Equipment

MT: power supply is required to operate yoke magnet

PT: no power supply needed