Currents generated by ICCP systems and sacrificial anodes can enter the propeller shaft through the propeller. If left undrained, this can cause stray currents that might cause corrosion in the propeller shaft bearings or gearboxes.

Our shaft grounding (shaft earthing) systems drain any current sent out by the anodes. This prevents corrosion and premature failure of vital parts of the propulsion train. Generally speaking, every propeller shaft on a ship should be fitted with a grounding system.

Contact us if you have a question or want to receive a quotation!

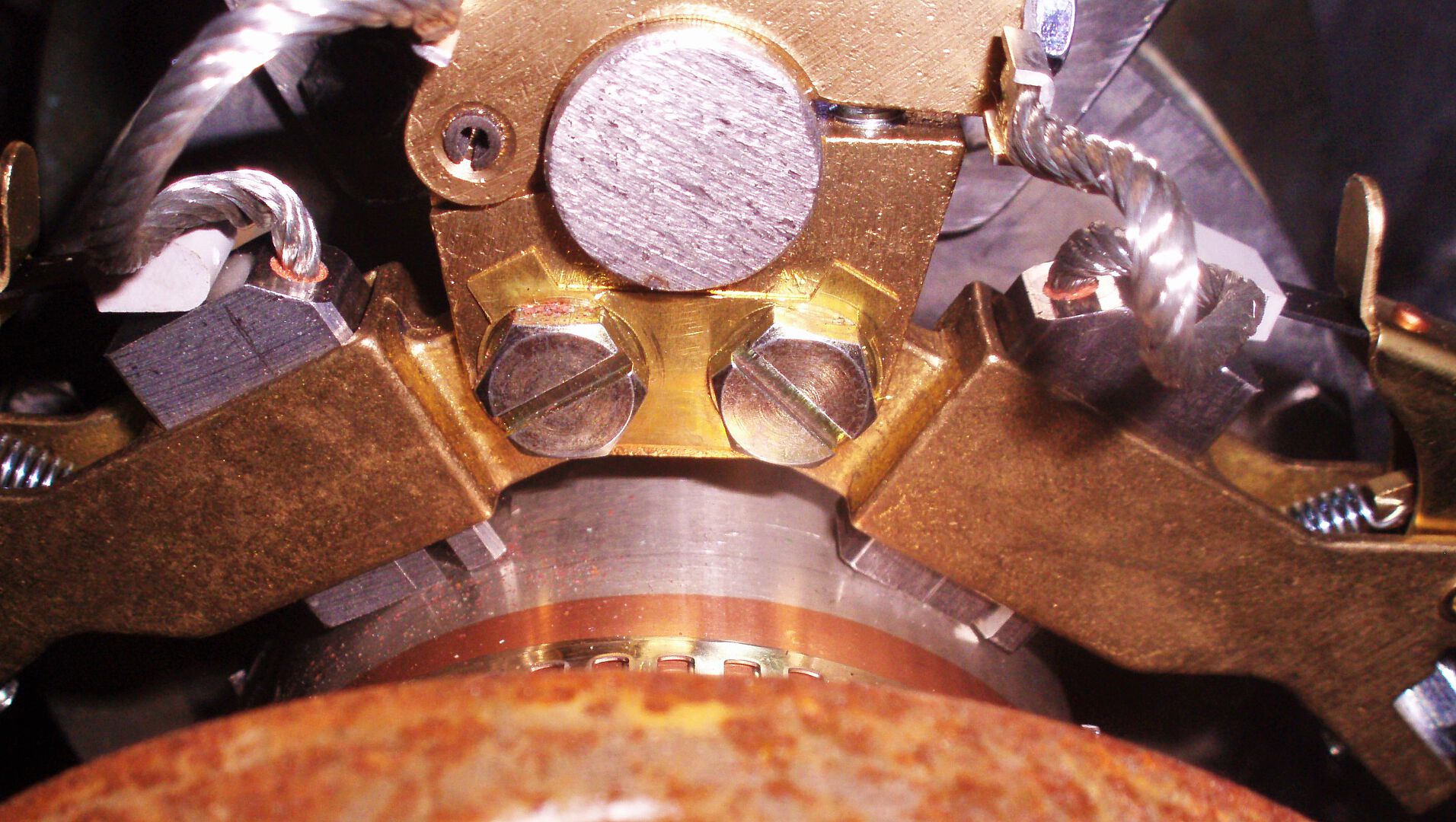

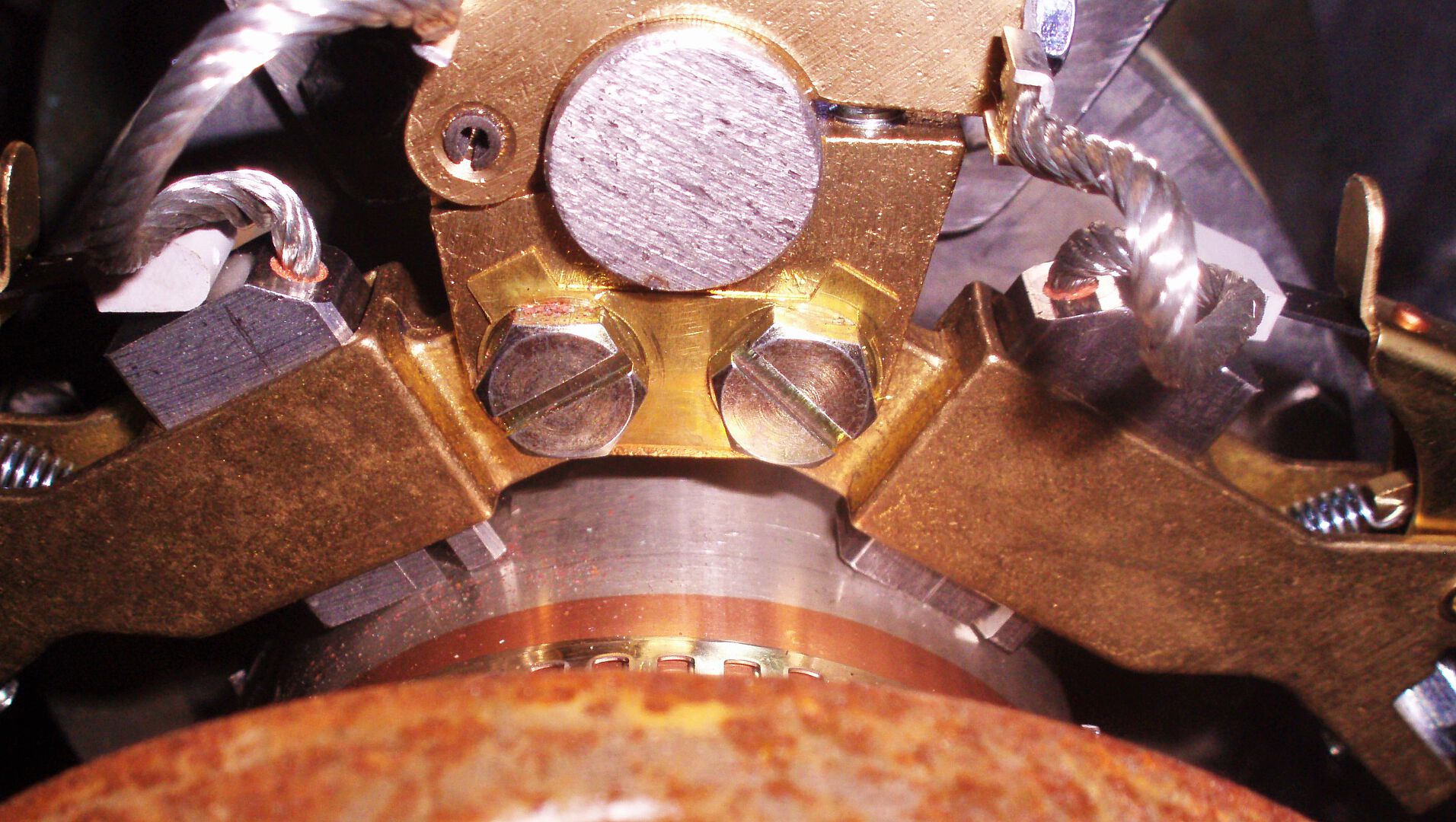

The system consists of a set of silver brushes sliding over a copper slip ring with a silver strip. The silver brushes are pressed on the silver strip, ensuring maximum contact with the least resistance and thus allowing for optimal drainage of the current. The brush holders are mounted around the shaft utilising spindles, of which we have two types:

Replacement silver brushes can be orderd through our contact form.