Prevent damage from electrical currents

When propeller shafts are rotating, harmful electrical currents can occur, generated by ICCP systems and sacrificial anodes. These currents lead to premature wear or severe damage to bearings and drive systems. If these stray currents are not discharged, they can cause corrosion in the propeller shaft, bearings, and gearboxes.

MME Group’s Shaft Grounding System prevents this by safely discharging the electrical load, significantly extending the service life of your drive and propulsion system. Normally, every propeller shaft on board of a vessel should be equipped with a grounding system.

Compatible with cathodic protection

MME’s shaft grounding systems can be used in combination with both sacrificial anodes (SA) and impressed current systems (ICCP). This way, your vessel receives double protection against harmful currents and corrosion.

Contact us if you have a question or want to receive a quotation!

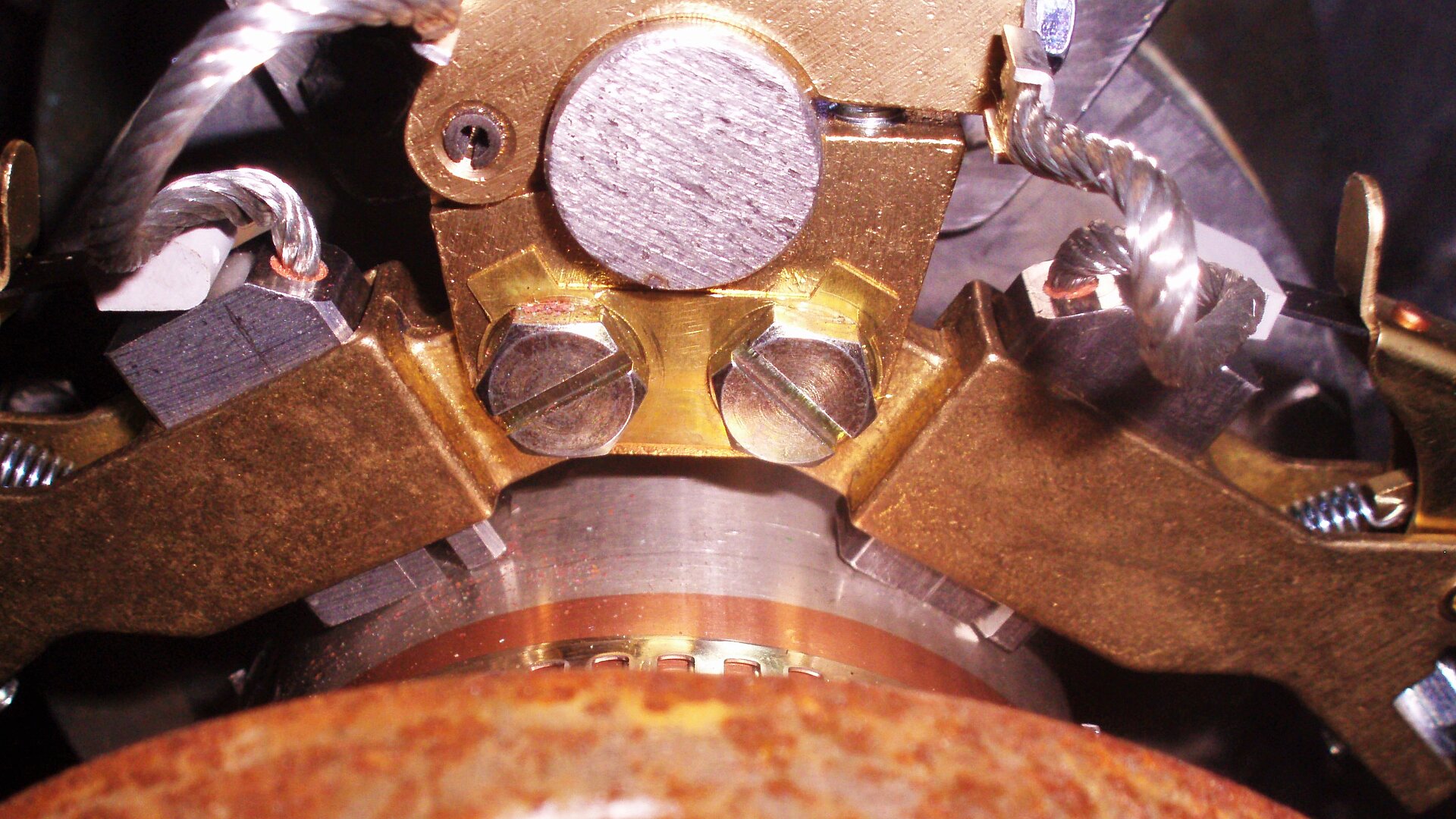

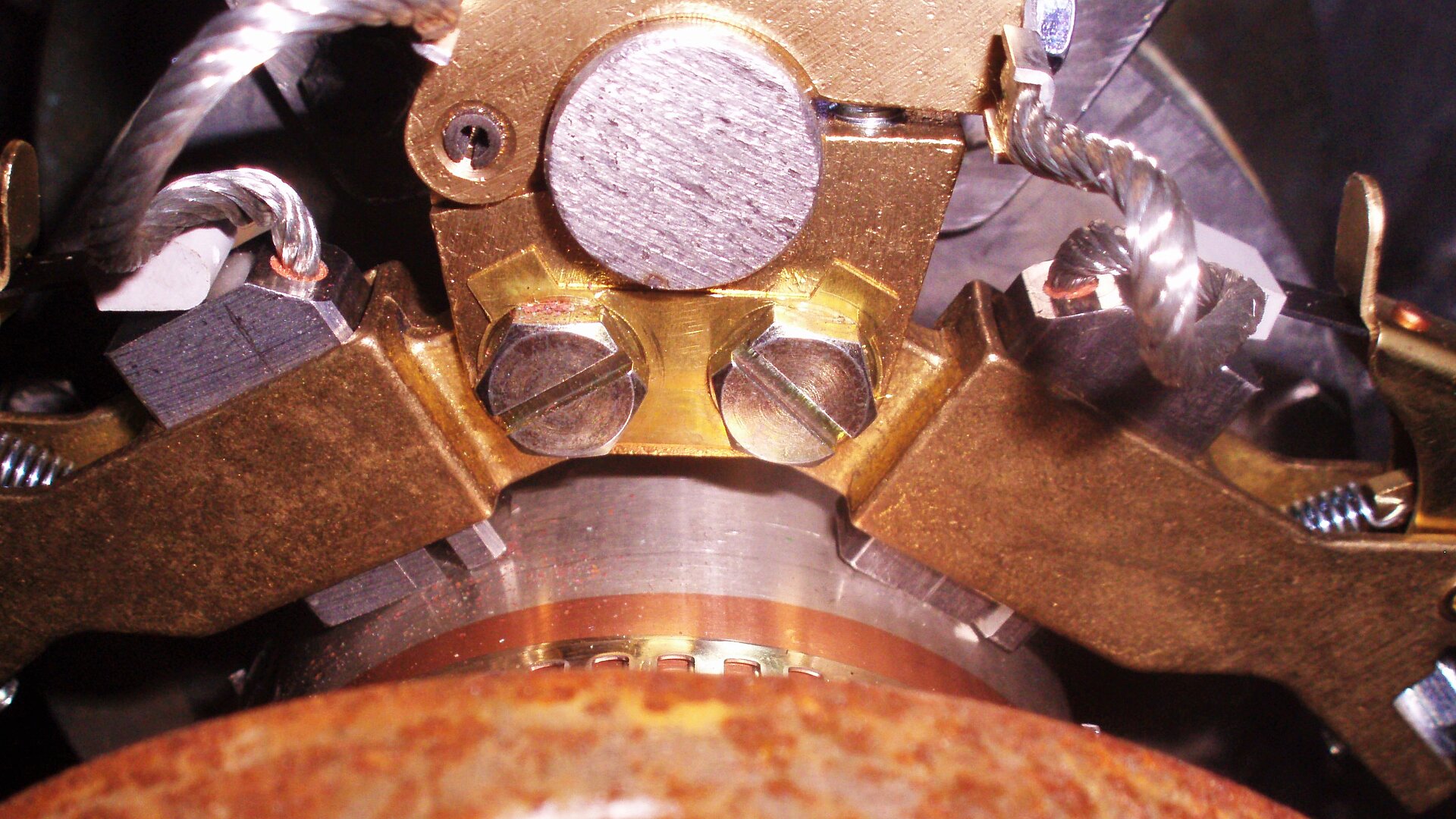

The system consists of a set of silver brushes sliding over a copper slip ring with a silver strip. The silver brushes are pressed against the slip ring for maximum contact and minimal resistance, ensuring optimal discharge of stray currents.

The brush holders (in which the silver brushes) are mounted around the shaft utilising spindles of which we have two types:

Replacement of silver brushes, slip rings or brush holder assemblies can be ordered through our contact form.

We do not only supply the components but also provide support with advice, installation, monitoring, and maintenance.

In addition to the mechanical protection of our shaft grounding system, MME Group has developed an advanced monitoring system specifically designed to perform real-time measurements and analysis of critical vessel components.

This intelligent measuring system continuously records the performance of your Shaft Grounding System and provides insights into wear and electrical load.

It is particularly suitable for monitoring the grounding of propeller shafts and thruster shafts, ensuring optimal performance and early detection of potential issues. In this way, you prevent unexpected downtime and can schedule maintenance at the right moment.

For more information about our Digital Monitoring Box for Shaft Grounding Systems and our other cathodic protection products, visit our ICCP products page.

Keep your propeller shaft protected, your operation reliable and your maintenance predictable.

Contact MME Group for more information or a quotation for your Shaft Grounding System via our contactform below.